Modified Alumina for automobile exhaust AC-100

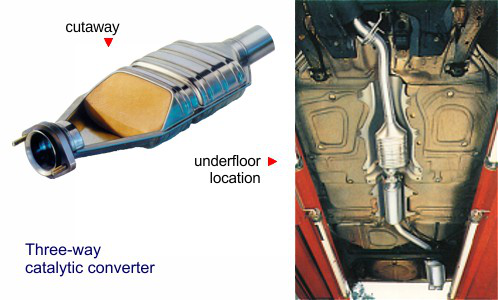

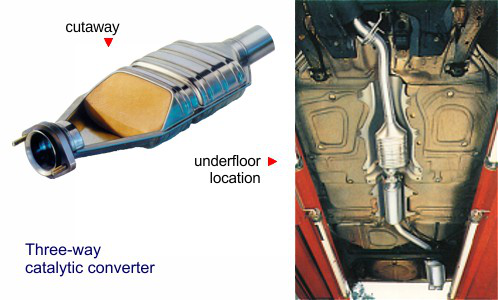

Following the adoption of the CAA and the resulting vehicle

emission standards, oxidation catalysts have been commercialized in

the USA in the mid-1970s (first commercial application in model

year 1975 cars) to control emissions of CO and HC from spark

ignited (SI) gasoline engine applications. Three-way catalyst

technology, introduced in the 1980s, made it also possible to

control NOx emissions from SI engines at levels that are

significantly lower than NOx emissions from diesel engines.

Finally, in the 1990s, oxidation catalysts have been introduced to

diesel fueled cars in Europe, as well as to heavy-duty diesel bus

and (to a limited scale) truck engines in the USA. Since as early

as the 1970s, diesel catalysts have also been used in some

occupational environments, such as underground mining. Most

catalysts in all of the above applications use noble, platinum

group metals as their active components.

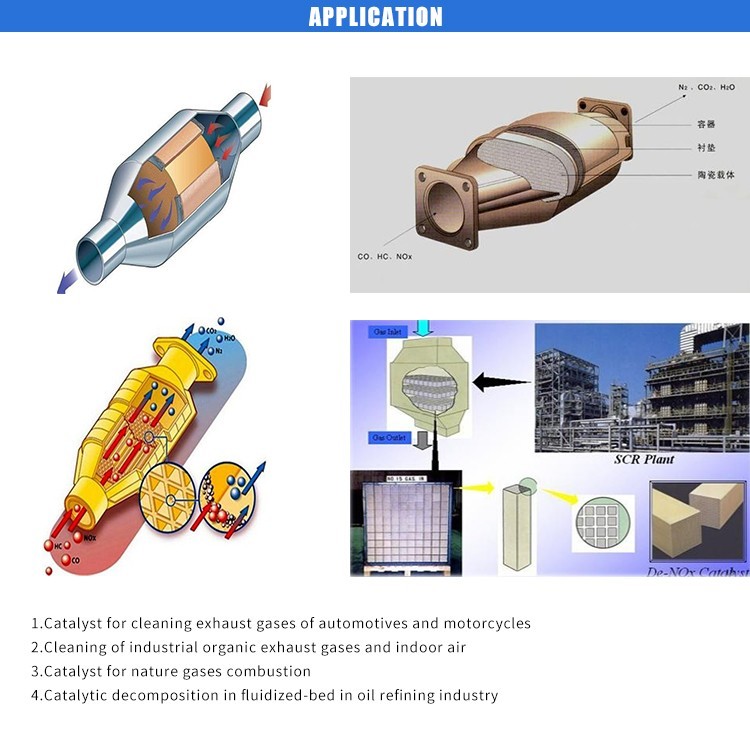

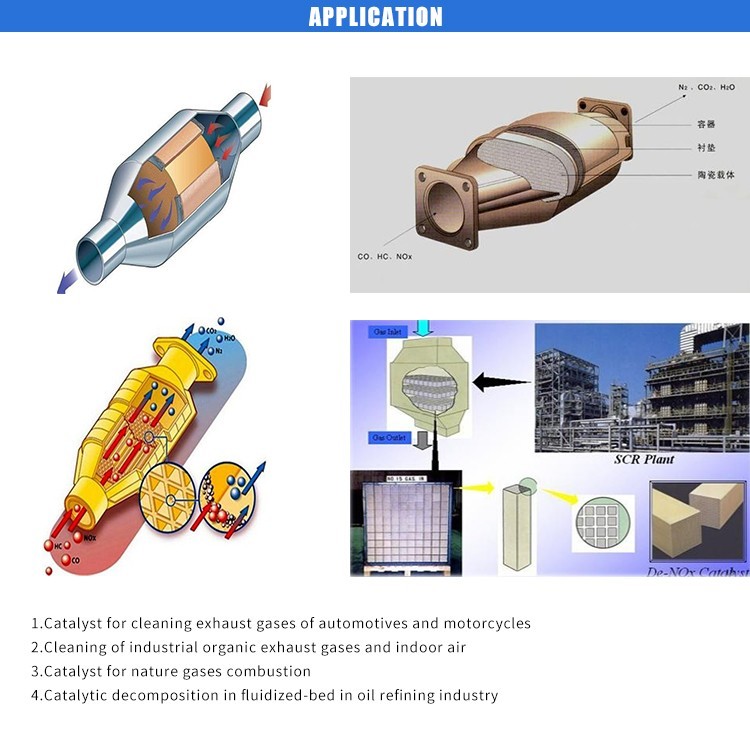

【Application】

(1) Purification and catalysis of automobile and motorcycle exhaust

gas;

(2) Industrial organic waste gas purification and indoor air

purification;

(3) Natural gas combustion catalysis.

(4) Fluid catalytic cracking in oil refining industry.

【Specification】

| TYPE | AC-100 |

| Color | white |

| Chemistry composition | La2O3 | 4±1% |

| Al2O3 | ≥95% |

| Physical property | D50(μm) | 3-6 |

| Fresh BET(m2·g-1) | >150 |

| Aged BET(1000℃ 4h/m2·g-1) | >100 |

【Product features】

This coat, which may comprise a top coat overlying the first coat,

contains a co-formed (e.g., co-precipitated) rare earth

oxide-zirconia support on which a first rhodium catalytic component

is dispersed, and a second activated alumina support having a

second platinum catalytic component dispersed thereon.

The coat may also include a second rhodium catalytic component, and

optionally, a third platinum catalytic component, dispersed as an

activated alumina support. The present invention also provides a

method for treating engine exhaust gases by contacting the gases

under conversion conditions with the catalyst composition.

(1) High temperature resistance and high aging ability: the

modification of lanthanum oxide can inhibit the sintering of -Al2O3

and improve the high temperature anti-aging ability of the

products.

(2) High solubility index and viscosity: the modified alumina is

easy to gel solution and has high viscosity, which can reduce or

not use aluminum sol, improve the coating performance and reduce

the shedding rate.

(3) The particle size distribution is moderate: the medium diameter

of the material is controlled to be 3-6 μ m and the particle size

distribution is narrow.

(4) Good product stability: advanced production technology and

production equipment, standardized management, to ensure the

stability of the product.

【Packing】 25kgs/poly-drum ,500kgs/pallet

1 Q: Are you trading company or manufacturer?

A: We are a professional factory with more than 12 years of

experience in this field. If you are convenience, we welcome you to

visit our company.

2 Q:What's the guarantee ?

A:1). Our guarantee for 12 months.

2). 18 hours' technical support by email, video or calling

3). English manual and video tutorial

3 Q:Do you provide equipment operation training?

A:Yes. We can will send one or two professional technicians (one is

electrical engineer, one is mechanical engineer) to install and

adjust the machines and help train the workers.

4 Q:What documents you provide?

A:Usually, we provide Commerical Invoice, Packing List, Bill of

loading, COA , and Origin certificate. If your markets have any

special requirements, let us know.

Shanghai Gona Industrial Co.Ltd is founded in 2006, and located in

Songjiang Industrial District, rounded by National Engineering

research Center of Ultrafine Powder(NERCUP).Our company is a

R&D company specialized in technology development of functional

powder materials.Now we have three production bases and one R & D Center.One is

located in Baotou city inner Mongolia which produces cerium oxide

polishing powder;One is located in Zhejiang which produces alumina

for Li+ battery separator.Another one and the R&D center are

located in Shanghai.