Activated Alumina for automobile exhaust AC-100

Activated Alumina Powder is manufactured for water adsorption and

filtration applications by adsorbing impurities from the

surrounding environment. Activated alumina powder can be used in a

wide range of applications including the production of chemicals,

pharmaceuticals, and in static or dynamic dehydration applications.

This activated alumina offers a high adsorption capacity for both

static and dynamic adsorption processes.

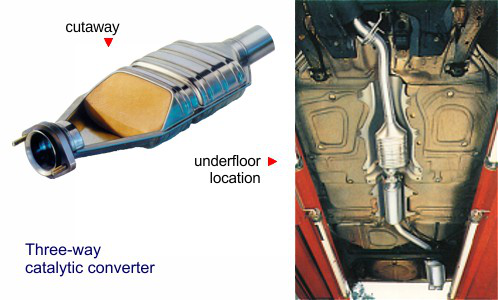

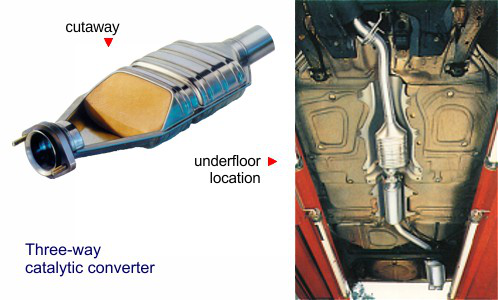

The exhaust gases emitted from internal combustion engines usually

contain hydrocarbons, carbon monoxide, carbonyl compounds, etc.,

resulting from partial or incomplete combustion of fuels, and

nitrogen oxides produced by the reaction between oxygen and

nitrogen gases contained in the air used for the combustion of

fuels at elevated temperatures

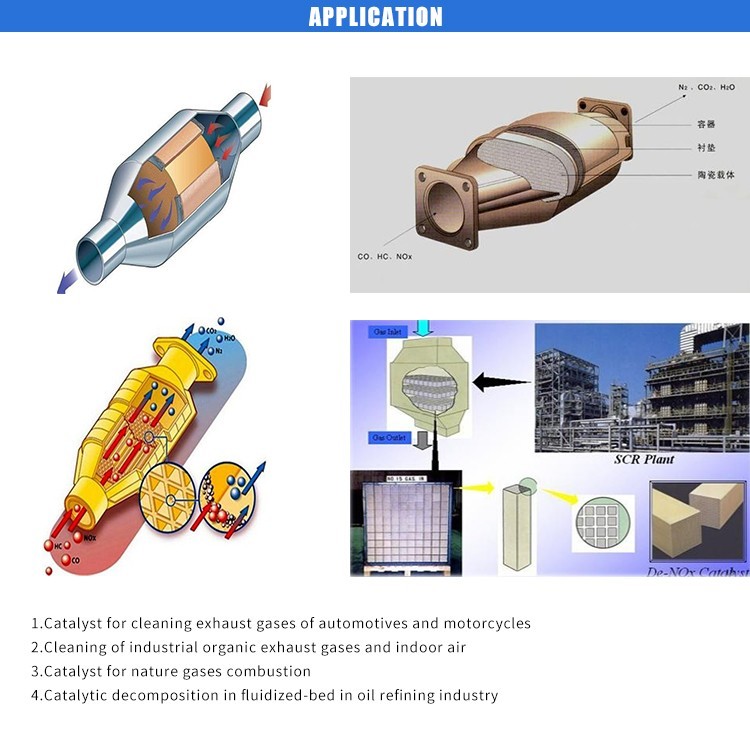

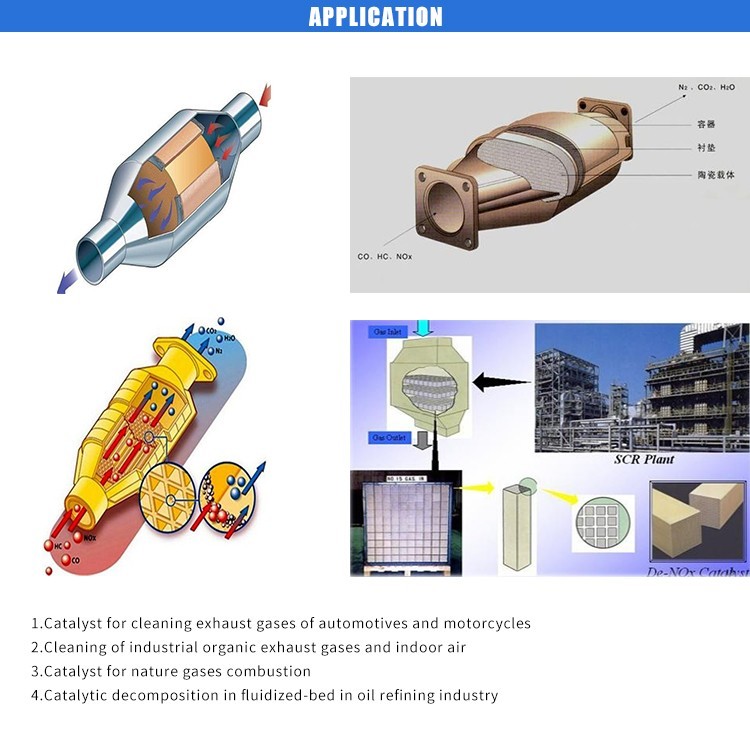

【Application】

(1) Purification and catalysis of automobile and motorcycle exhaust

gas;

(2) Industrial organic waste gas purification and indoor air

purification;

(3) Natural gas combustion catalysis.

(4) Fluid catalytic cracking in oil refining industry.

【Specification】

| TYPE | AC-100 |

| Color | white |

| Chemistry composition | La2O3 | 4-5% |

| Al2O3 | ≥65% |

| Physical property | D50(μm) | 3-6 |

| Fresh BET(m2·g-1) | >180 |

| Aged BET(1000℃ 4h/m2·g-1) | >150 |

【Product features】

The first coat includes a stabilized alumina support on which a

first platinum catalytic component is dispersed and bulk ceria, and

may also include bulk iron oxide, a metal oxide (such as bulk

nickel oxide) which is effective for the suppression of hydrogen

sulfide emissions, and one or both of baria and zirconia dispersed

throughout the first coat as a thermal stabilizer.

The second coat, which may comprise a top coat overlying the first

coat, contains a co-formed (e.g., co-precipitated) rare earth

oxide-zirconia support on which a first rhodium catalytic component

is dispersed, and a second activated alumina support having a

second platinum catalytic component dispersed thereon.

(1) High temperature resistance and high aging ability: the

modification of lanthanum oxide can inhibit the sintering of -Al2O3

and improve the high temperature anti-aging ability of the

products.

(2) High solubility index and viscosity: the modified alumina is

easy to gel solution and has high viscosity, which can reduce or

not use aluminum sol, improve the coating performance and reduce

the shedding rate.

(3) The particle size distribution is moderate: the medium diameter

of the material is controlled to be 3-6 μ m and the particle size

distribution is narrow.

(4) Good product stability: advanced production technology and

production equipment, standardized management, to ensure the

stability of the product.

【Packing】 25kgs/poly-drum ,500kgs/pallet

1 Q: Are you trading company or manufacturer?

A: We are a professional factory with more than 12 years of

experience in this field. If you are convenience, we welcome you to

visit our company.

2 Q:How about the validity of the products?

According to the products you ordered.

3 Q:What documents you provide?

Usually, we provide Commerical Invoice, Packing List, Bill of

loading, COA , and Origin certificate. If your markets have any

special requirements, let us know.

4 Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance, balance before shipment.

If you have other questions, please feel free to contact us.

Shanghai Gona Industrial Co.Ltd is founded in 2006, and located in

Songjiang Industrial District, rounded by National Engineering

research Center of Ultrafine Powder(NERCUP).Our company is a

R&D company specialized in technology development of functional

powder materials.

Our company is always paying great attention to the intellectual

property and independent development, and pursuing innovation of

science and technology. Our company has been recognized as

“High-Tech Enterprise of Shanghai” since 2008.